Committed to Quality

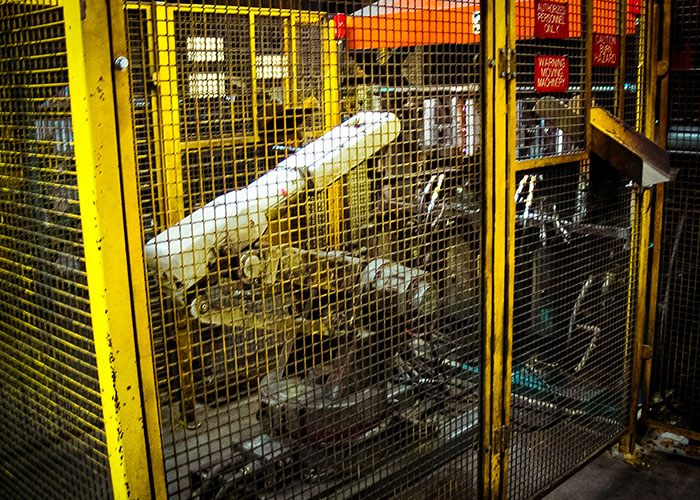

Riverside Foundry Inc is a leading non-ferrous sand-casting foundry in New Hamburg, Ontario celebrated for its dedication to impeccable craftsmanship and top-tier metallurgical quality. At the heart of Riverside's operations are its expansive facilities with 77,000 square feet of manufacturing space. Completely equipped with computer-controlled systems meticulously engineered to handle large production runs, this cutting-edge facility ensures unparalleled control and quality to accommodate medium to large-scale casting requirements across various alloys. Committed to fulfilling the expectations of our customers, we manufacture quality non-ferrous castings supported by technical services. With over five decades of experience, our seasoned professionals prioritize attention to detail, offering tailored guidance to optimize product quality.

Key Alloys

Key Base Alloys

Alloys Poured

- Copper Base Leaded: C83300, C83400, C83600, C84400 C86300, C86500, C87200, C87300, C87600, C87610, C90700, C92200, C95400, C95600

- Copper Base No Lead: C87850, C89833

Alloys Poured

- Aluminum: 319, 356, 535, 713

- Zinc: ZA12

- Other alloys may be available upon request

Capabilites & Services

Capabilities

- Hunter 10 Automatic Molding Machines

- Airset Floor Molding

- CNC Fully Machined Patterns, Coreboxes & Trim Dies

Casting Size & Weight

Hunter

- Casting weight from .1 lbs to 10#

- Weights below and above also available

- Size of Hunter plate 14x19

Airset

- Casting weight – up to 100#

- Size: up to 30x40

Value-Added Services

- T5/T6 Heat Treating

- Machining

Our Certifications

Industries Served

- Fire Suppression and Safety (sprinklers, valves, hydrant components)

- Water (faucets, nozzles, plumbing components)

- Electric (transmission components)

- Gas (meter components, valves)

- Transportation (oil pump components, off road vehicle components, hinges, latches

- Plaques (memorial and dedication)