Committed to Excellence

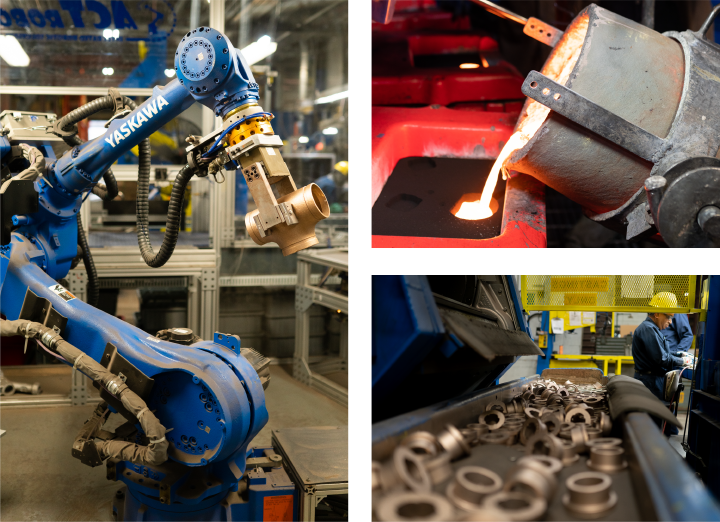

We are committed to maintaining the utmost levels of manufacturing excellence, which is made possible by our team of experienced professionals and our engineering team consisting of more than 10 engineers. Our dedication to upholding a Quality Management System (QMS) is integrated throughout all levels of our organization. Our ISO certification guarantees that the highest quality standards are reached. We implement a comprehensive system of testing and inspection procedures throughout the entirety of the production cycle to guarantee the quality and functionality of our castings.

Key Alloys

Key Alloys

Alloys Poured

- CU: C80100, C83300, C83600, C84400, C86300, B61 C92200, C85200, C86500, C87200, C87600, C90300, C90500, C90700 Al Bronze C95300, C95400, C95500, NiAlBrz C95800, Lead Free C89836, Eco Brass C87850, Cupro Nickel C96400, C96200

Alloys Poured

- Monel: M-30C, M-30H

- Al: A356.2, B319,712,713, Almag 535.0, ZA12

- Zn: ZA-12

Capabilites & Services

Capabilities

- Green sand floor molding

- Jolt Squeeze Manual Molding Machines & Rotolift Molding Machines

- No Bake Floor Molding Operation

- Sinto and Hunter Automatic Molding Machine

Casting Size & Weight

Casting weight from 0.5 to 3,000 lbs

Casting sizes from 0.5 to 75 inches

Value-Added Services

- Ability to Reverse Engineer any part including worn-out i.e. Fully integrated to provide Reverse Engineering services

- Casting Simulation Software to predict discontinuities in advance of launching new products to cut down trial & error approach

- Fully integrated to provide Design/CAD modelling services i.e. From 2D drawing to 3D model

- 3D Scanning, CMM Probe and 3D “Sand” printing

Our Certifications

Industries Served

- Architectural

- Fire Protection

- HVAC (Boilers)

- Industrial (Automobile, Machinery)

- Military

- Power Distribution (Transformers)

- Public Sector

- Resource Extraction (Oil & Gas, Mining)

- Water Works