Committed to Quality

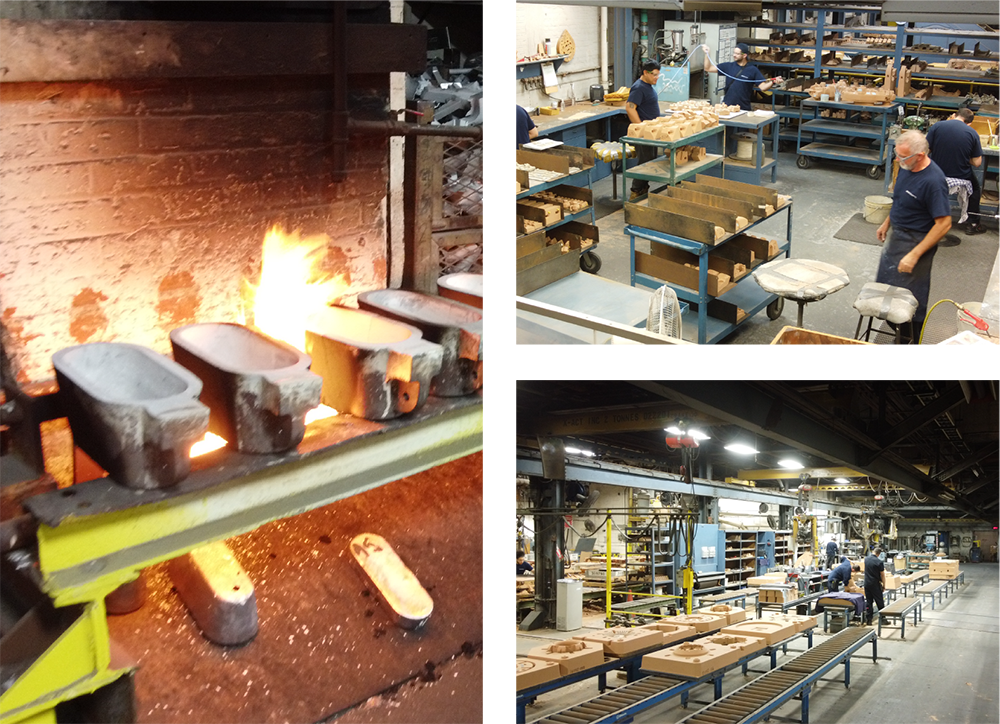

At Mitchell Aerospace, we take great pride in our unrelenting commitment to quality and adaptability. Mitchell Aerospace is a trusted provider of complex and sophisticated casting solutions for some of the leading aviation and transportation sectors worldwide. Our unwavering commitment to quality has earned us the trust of these top-tier industries. We operate a specialized metal casting production facility using chemically bonded sand-molds that caters to highly demanding specialized industries such as aviation, space, defense, and energy. We are committed to continuous innovation and improvement to ensure that we meet the highest standards of quality and excellence in our products and services.

Key Alloys

- Aluminum: 203, 354, 355, A356, A/F357, A520, 850

- Magnesium: EV31, ZE41

In-House Capabilities & Services

- 3D Laser Scanning

- Full Testing Laboratory

- Magnesium and Aluminum Welding

- Proof Machining

- Spectrometry (OES)

- Pattern Shop

- Heat Treating

- Tensile/Destructive Testing

- Radiographic (X-Ray) Testing

- Fluorescent Penetrant Inspection (FPI)

Our Certifications

- ISO 9001:2015 & AS 9100 Rev. D with Intertek registrar

- Scope of Registration: Manufacturer of Precision Aluminum and Magnesium Sand Castings

- Certificate for Controlled Goods Program with Public Works and Government Services Canada

- Approvals from: Pratt & Whitney, Collins Aerospace, General Dynamics and other OEM’S

Industries Served

- Aerospace (Turbine Engines, Engine inlet fan, Intermediate cases, Engine accessory gearboxes, APU gearboxes)

- Military

- Power Generation (Turbine Engines)